Lime: an introduction

Practical Action

Almost any fuel can be used in lime burning. Traditionally, wood was most commonly used

but increasing cost, environmental concerns and deforestation have restricted its use. Coal is

probably the most common fuel used in recent years. Others fuels include oil, gas, some

agricultural wastes and even, in a few cases, peat.

Burning

The techniques employed in burning lime can

vary considerably. The simplest (and least

efficient) method consists merely of a circular

pile of logs with limestone heaped on top of it.

This is then ignited and is likely to produce

less than 500kg of lime per burn.

At the other end of the scale, sophisticated

and energy-efficient rotary kilns operating

continuously can produce over 500 tonnes of

lime per day.

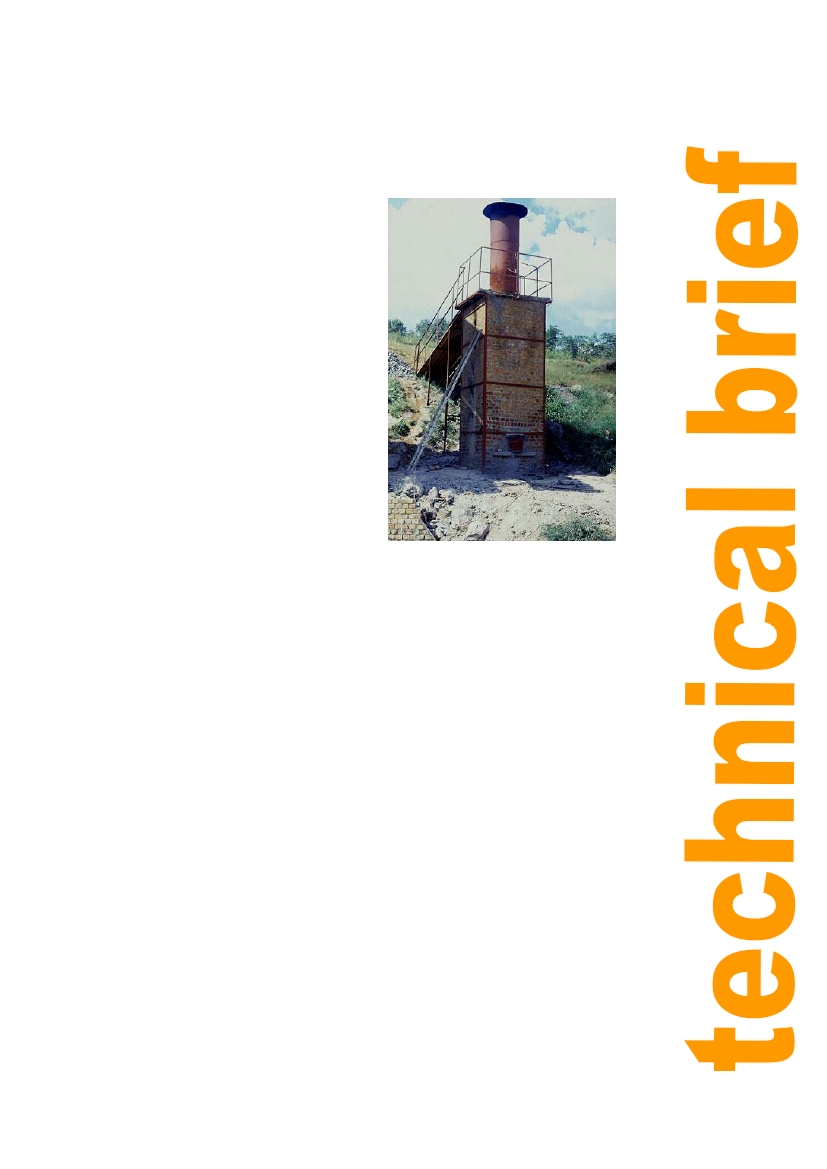

Probably the most common type of lime kiln is

the vertical shaft, of which there are many

variants. Basically they consist of a tall,

chimney-like, cylindrical shaft. Limestone is

loaded at the top and while being burned falls

slowly under gravity as lime is withdrawn from

the bottom.

The limestone is first pre-heated, burned and

then cooled as it passes slowly through the

kiln. Vertical shaft kilns will normally produce

between 2 and 250 tonnes of lime per day

depending upon kiln size.

Figure 2: A vertical shaft kiln for small-

scale production of lime. Chegutu,

Zimbabwe. Photo: Practical Action / Kelvin

Mason.

Other leaflets in this series describe a number of kiln types and give case studies of lime

production at varying levels of output and mechanisation.

Hydration

Hydration, in small quantities, can be undertaken manually by sprinkling water onto a pile of

quicklime which is then turned and mixed with a rake as more water is added. In large

quantities, hydration is normally automated and done in large hydrators where measured

quantities of water and quicklime are fed in and mechanically agitated.

During hydration, the quicklime lumps will disintegrate to a fine powder. For high quality

limes some form of screening and/ or classification, during which the lime is sorted by

particle size and density, will be required to grade the lime. Hydrated lime is normally

supplied and sold bagged, as a dry powder.

If quicklime is hydrated with an excess of water and well agitated, it forms a milky

suspension known as milk of lime. Allowing the solids to settle and drawing off the excess

water forms a paste-like residue known as lime putty. Lime in this form is considered, by

many, to be preferable for use in building as it ensures complete hydration, produces

excellent mortars and, if kept in a saturated condition, will not deteriorate over time.

Dolomitic and hydraulic limes

In some locations, raw material with high calcium carbonate contents will not be available.

This may not be a constraint for lime used in the construction industry since lime containing

impurities can be tolerated and may even have advantages.

2